When we talk about large industries, we need to be very clear that these industries have specific demands when it comes to equipment. There are kinds of equipment and heavy machinery that need to be installed in order to meet the day-to-day requirements and manufacture a certain number of units. Whether we talk about electric motors, pumps, valves, or hydraulic systems, we must understand that there is a considerable need to maintain inventory for these products. In case there is any kind of mishaps, you will never to able to serve the demand for equipment in the industry.

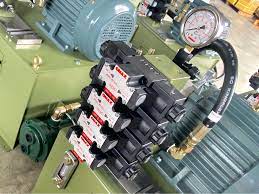

Hydraulic systems are the most expensive and most extensive systems in any industry. They are capable of moving any load and have the capacity to cope with large loads without any kind of pulleys or gears. Because hydraulic systems have fewer moving parts when compared to other types of machines, they are simple and a lot easier to maintain. The only purpose of the hydraulic system is to create motion that can carry heavy loads. Hydraulic systems transmit power by using the pressure of an incompressible fluid within a sealed system. Even if the speed of the hydraulic system changes, they will constantly deliver you the same torque. Because hydraulic systems have to operate with fluids, people need to be cautious to avoid any leakages.

The efficiency of the hydraulic systems can come down if you are not able to make the proper selection and choose the correct fluids. In order to retain the performance, certain things need to be checked. A little extra attention to hydraulic system maintenance can do wonders and improve overall efficiency. So, here are simple ways to improve efficiency:

Clean the reservoir: when the hydraulic system is down, you must check the reservoir. The reservoirs in this system need to be cleaned from time to time so that things are tackled at the earliest. Not only does the reservoir store the oil, but it also keeps the system away from contaminants. In case there is any kind of contaminants in the reservoir, the oil will also become dirty and affect the efficiency of hydraulic systems. There will be sludge, and the oil will start to break down in the system creating further issues. So, to avoid any system failure, the reservoir needs to be cleaned at the earliest.

Cleaning and flushing of the system: Hydraulic system is a cumbersome system, and there are so many things that you need to consider to maintain the hydraulic system properly. When fluids and oils are removed from the hydraulic system, you must make it a point to filter the storage tank with proper flushing and filtering. When the entire system is cleaned correctly, the oil will also be cleaned for longer.

Cut down the oil level switches: It is easy to set two oil levels in the hydraulic system. We do not realize that we will lose gallons of oil when we arrange the system this way. Even if the hose ruptures, the oil loss will be minimal if we set the warning switch at a much higher level.