The COVID-19 crisis has strapped a rocket to digitization, pushing every industry to rethink the way they service, manufacture, and sell their wares. Further, the climate crisis looms, pressing upon us a sense of urgency to rethink the status quo of our industrial and economic systems.

This trend towards global evolution has ensured that human beings can no longer operate in the same way we have for millennia. We must dramatically rethink the way industries operate and how we develop solutions to challenges, new and old.

In a way that hasn’t been seen before, these global crises are pushing industries to fast-track their digital and technological innovation. This new world of radical reinvention is the perfect environment for technologies like 3D printing to really shine – to become instrumental in the areas of manufacturing and design.

Today we’re going to look at a few of the latest news bites and trends around 3D printing.

CNT-infused polymeric inks make a splash

Research out of the Michigan Technological University has demonstrated the printing of carbon nanotube (CNT) infused epoxy inks. CNTs are particularly lorded for their high specific strength, but they’re difficult to manufacture at scale. This new research, however, may show one way of scaling the material up.

What does this mean for the future of 3D printing? Essentially, the CNT-epoxy polymer inks are conductive and strong. This means they may be ideal for use in electronics and aerospace manufacturing.

World’s largest 3D printer being built by GE, Voxeljet and Fraunhofer Institute

GE Renewable Energy, Fraunhofer IGCV, and printer company Voxeljet AG have joined forces to develop the world’s biggest 3D printer. The printer is to be used to produce molds that will create large composite components for GE’s Haliade-X offshore wind turbines.

Named the Advance Casting Cell (ACC), the printer is a modular system able to print molds for castings up to 60 metric tons and 9.5 meters in diameter. A pattern and mold of this size would typically take over ten weeks to develop. With this new printer, manufacturers say it would be able to be produced in just two weeks.

The ACC is expected to launch later in 2021, with printer trial runs starting early 2022.

3D printed motors are in development

Electric motors are gaining popularity in the world of automobiles, with businesses all over the world trying for a share in the EV sphere. With such interest comes innovation.

While motors themselves haven’t seen much of a change in design since their initial invention, advances in manufacturing processes have seen automotive designers experimenting with innovative measures. The goal? Weight reduction and performance gains.

There have already been a few examples of additive manufacturing being applied to electric motor production but researchers from the Manufacturing Technology Centre (MTC) are pushing further. They’ve been working on developing a motor with the most 3D printed components ever seen, including 3D printed cooling systems.

3D printed bee homes to help save the bees

As the number of bees dwindles, researchers scrabble with ways to boost public interest in the crisis. The newest idea? 3D printed bee homes.

A group of researchers from Lancaster University is implementing a plan to 3D print bee homes for distribution to the public. This bee-awareness outreach effort involves the design of the world’s first webcam-equipped “BeeBox”. It’s hoped that these new bee homes won’t just spur people to care more about the environment, but will also allow researchers to gain insights into the lives of bees that have been closed off until now.

The BeeBoxes are to be printed with recycled plastic and are made to be mounted on the ground or in trees.

3D Systems launches VisiJet Wax Jewel Red

3D printer manufacturer 3D systems just announced a new addition to its material portfolio: VisiJet Wax Jewel Red. The material is intended to enable more intricate designs for use in the production of jewelry.

Additive manufacturing has made a lasting impression on the jewelry industry, letting designers push their creativity to new levels. The introduction of VisiJet Wax Jewel Red specifically enables unmatched quality of lost wax casting, allowing artisans to design styles with even finer features.

Colorful seaweed-based bioink in development

Researchers from the Pacific Northwest National Laboratory (PNNL) have created a new seaweed-based bioink designed for use in 3D printing.

Named ArtSea Ink, the material is largely made out of alginate – a biodegradable, naturally occurring polymer traditionally found in seaweed. Alginate is low-cost, biocompatible, and is able to be used without heat to form a stable gel. This means it can be extruded at low temperatures to make up 3D designs.

The PNNL team also added fine mica pigment powders to the formulation. The result? A collection of vibrant, colorful inks that are perfectly suited to artistic applications.

A 3D printed microneedle vaccine patch is developed

Researchers at the University of North Carolina at Chapel Hill and Stanford University have developed a 3D printed vaccine patch that’s supposedly more effective than a traditional vaccine shot.

The microneedle patch apparently delivers an immune response 10 times greater than a traditionally administered vaccine shot. This is on top of other advantages such as the potential to be self-administered and easy, painless delivery.

The development of the technology is hoped to set a precedent for even faster global development of vaccines.

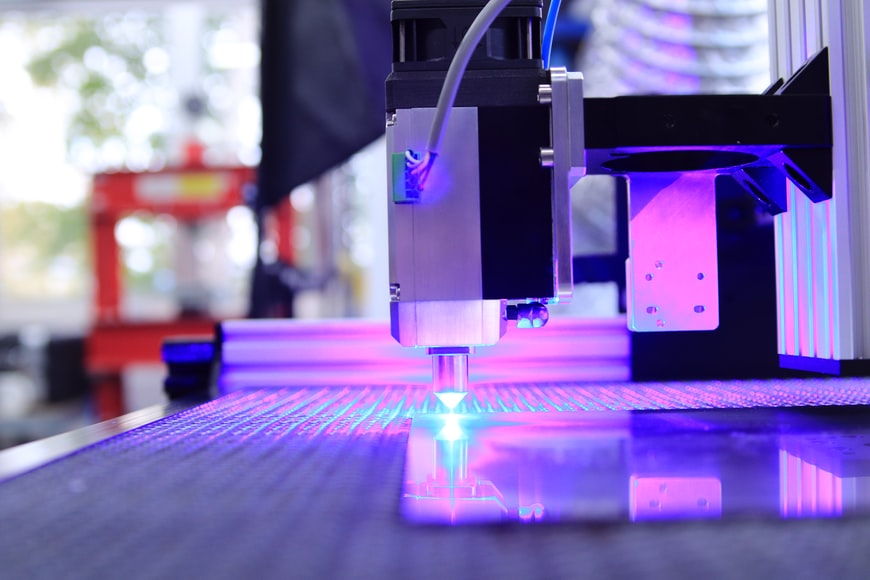

3D printed chicken cooked with robotic lasers

Researchers from the Columbia University School of Engineering and Applied Science have designed a way of cooking 3D printed chicken with robotic lasers controlled via software.

The “Digital Food” team experimented with various means of cooking by exposing raw 3D printed chicken structures to both infrared and blue light. The cooking depth, moisture retention, color development, and flavor differences were then compared to traditional, stove-cooked meat.

Why cook meat in this way? The scientists wanted to see if they could produce a heating method with the same degree of resolution as 3D printing.

3D printed sensor detects exposure to harmful herbicide

Scientists at DL ADV-Tech and Washington State University (WSU) have utilized additive manufacturing technology to design a way to detect exposure to the herbicide glyphosate, which is potentially carcinogenic.

The test kit is made up of a number of nanotubes covered with 3D printed sensors and uses technology similar to that used in glucose monitors. The difference? It deploys currents to assess glyphosate levels.

The technology is doesn’t require special storage and is low-cost which makes it ideal for use in measuring exposure to potentially harmful materials.

700 grams of chicken fat cultured in meat-printing “breakthrough”

Food-tech firm MeaTech has hit another milestone in its mission to create a tasty, eco-friendly 3D bioprinted alternative to organic meat products.

The first biomass 3D printed demonstration of its kind, the company has cultivated just over 700 grams of pure chicken fat within a single run. The deposit apparently behaves just like real fat. Pending approval, MeaTech has plans to produce it at a pilot plant next year, marketing it as a taste-enhancing ingredient.

Grimes wears a 3D printed gown for the Met Gala

The Canadian musician Grimes took to the 2021 Met Gala red carpet in a gown by fashion designer Iris Van Herpin. The gown is striking in and of itself, but its creation is particularly interesting – it was made using 3D printing techniques.

Composed of a nude illusion bodice that boasts hand-cast lightning bold shapes arranged in a 3D laser cut pattern, the gown is the latest high-profile piece from Van Herpen that uses digital manufacturing techniques in its creation.

The gown took a reported 900 hours to perfect and made an epic splash on the runway.

3D printed smart glasses are brought to market

Luxexcel, a prescription lens 3D printing specialist, has announced a partnership with Optiswiss, another lens manufacturer. Together, they intend to bring 3D printed smart glasses to the mainstream market.

As part of the partnership, Optiswiss has installed Luxexcel’s VisionPlatform 7 at its lab, allowing the companies to manufacture 3D printed lenses for manufacturers en-masse. The lenses are intended for use in both regular glasses and advanced smart devices.

The partnership is set to put both businesses at the forefront of innovation in the smart eyewear industry. The combination of Luxexcel’s technology and Optiswiss’ experience is set to be a lucrative and innovative partnership.

The world is changing

COVID-19 has boosted the world into a constant state of urgency. Both regular consumers and healthcare professionals are being confronted with quality issues and shortages of both everyday consumer goods and essential medical products. This is due in large part to a global market model that is hinged on centralized mass manufacturing.

Products and services we once took for granted are no longer available or even appropriate – it’s essential that new solutions be developed rapidly. This is where 3D printing comes in.

Now you have a good grasp of the current trends and innovations within the context of 3D printing.

Read More….